A.Equipment overview

1.1 Application Fields:

It can be used to wash and dry semiconductor new material wafers, silicon, gallium arsenide, silicon carbide, mask plate, solar cell substrate, sapphire, lithium niobate, optical lens, disk, optical disc, medical glass substrate and other similar material wafers with high cleanliness. Can achieve similar imported equipment performance.

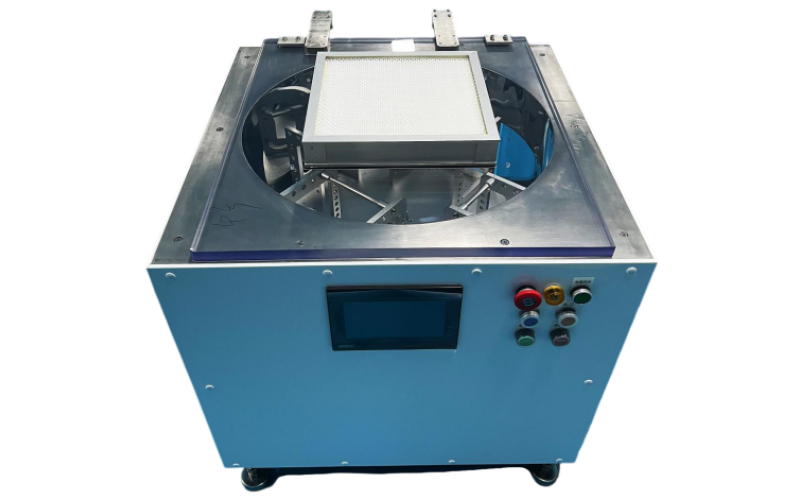

1.2 Appearance:

1) Overall dimensions: length 1059mm* Width 959mm* height 786mm

2) Body structure: stainless steel skeleton + imported PP plate shell

3) Suitable for 2 "-8" wafer processing

1.3 Process Parameters:

1) The PSC-X visual touch control system can store and run nine programmable recipes with each recipe step taking 0-999 seconds

2) Rotation speed: 300-1000r/min

1.4 Device Configuration:

1) Quick removal and replacement of rotor (single bolt)

2) Ultra-high clean valve fittings

3) No nitrogen, through the unique design of the air intake system, through the ultra-clean and efficient system filtration of fresh air, to achieve rapid air drying.

4) Flush cleaning function (optional)

5) Static elimination device and resistivity detection control and probe (optional)

1.5 Power parameters:

1) Electrical: 220V, 3KW

2) CDA: Φ10 gas pipe, pressure: 0.25-0.3Mpa, flow rate: 1L/min

3) DI: OD3/8 tube, pressure: 0.3-0.4Mpa, flow: 20-25L/min (no optional flushing function is not available)

4) Drainage: OD32mm(UPVC)