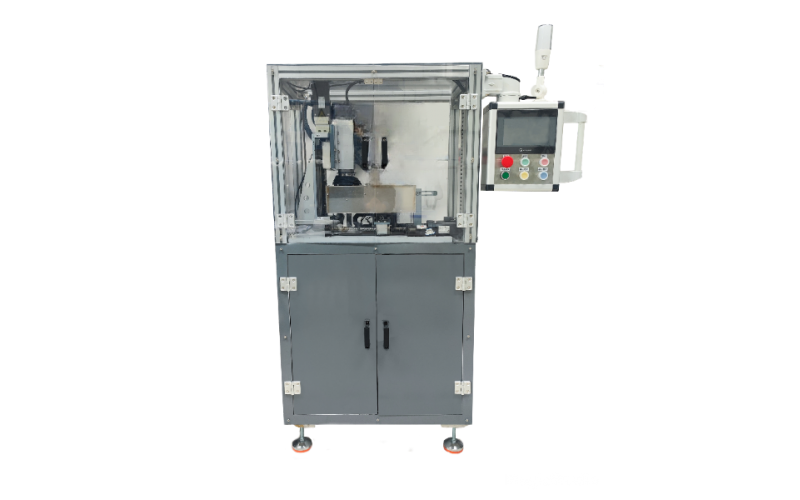

A.Equipment introduction

CNC wafer chamfering machine is a precision semiconductor production equipment, which is specially used for the precise edge chamfering treatment of silicon wafers, silicon carbide or sapphire wafers to eliminate burrs and sharp edges generated after cutting, improve the quality of wafer edges, and ensure the yield and safety in the subsequent chip manufacturing process.

B.Main technical parameters

Model | DJ-100 | DJ200 |

Wafer size | 2-4Inch | 4-8Inch |

Wafer thickness | 300um ~1200um customizable |

Suitable for wafer shape | OF edges or wafer edges |

Wafer edge shape | T�����、R����、TT、RR�、TR (customizable) |

0F length | 5mm~65mm |

0F shoulder fillet radius | 0 ~20mm |

Number of grinding circles | 1~5 |

Maximum speed of grinding wheel | 6000rpm |

Grinding speed | 1mm/s ~50mm/s |

precision | ±0.01mm |

Processing mode | Nc completes the wafer contour chamfering |

Wafer fixation method | Vacuum adsorption (customizable |

Wafer positioning mode | Mechanical fixture positioning |

Special function | Custom processing of shaped wafers |

Man-machine interface | Touch screen |

Cooling water | 0.3MPa ,RO water |

Compressed air | 0.55MPA |

Exhaust air | 10L/MIN |

Ambient temperature | 10℃-28℃ |

Power requirement | 220VAC±10%, single phase, 50Hz or 60Hz, 15A |

Equipment weight | 600KG |

C.Preparation before operation

3.1 Ensure that the power connection is stable and reliable and well grounded;

3.2 Check whether all components are in good condition, including but not limited to protective cover, workbench vacuum cups, grinding wheels, drives, etc;

3.3 Check whether the initial setting of the chamfer is correct before operation;

3.4 Confirm whether the cooling water (pressure requirement 0.3Mpa) and compressed air (0.55MPA) are opened;

3.5 Check whether the drainage water is connected to the sewer pipe.